Welding Consumables Market Sales, Revenue, Emerging Trends, Industry Segments, Profits and Regional Study

Key Highlights of U.S. Welding Consumables Market

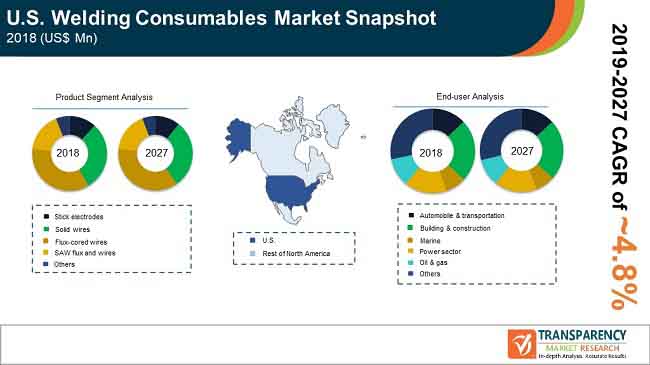

- The U.S. Welding Consumables market was valued at US$ 2.8 Bn in 2018 and is anticipated to expand at a CAGR of 4.8% during the forecast period

- The welding consumables market is driven by the increase in demand for building & construction across the U.S.

- Among the different product types, flux-cored wires is anticipated to be a key segment in the U.S. welding consumables market.

Key Drivers of U.S. Welding Consumables Market

- Building & construction has been the largest end-user of steel, as the latter is extensively used in building infrastructure components in residential, non-residential, and industrial construction sub-sectors. Growth in the building & construction industry is anticipated to be the major growth driver of the welding consumables market in the U.S. in the near future.

- The market is further expected to be fueled by the surge in the number of applications in which the different types of welding can be applied, such as ultrasonic welding for joining dissimilar materials or the welding of nonferrous metals in aerospace equipment. Currently, while arc, resistance and oxyfuel welding dominate the market, electron beam, friction-stir, laser, and ultrasonic welding methods have found several applications in verticals such as aerospace, electronics and packaging applications.

- Prominent welding methods are used in several typical market segments, and demand for them is subject to the cyclical nature of individual markets, although the diversity and number of markets in which welding is used mitigates the effects of this in the welding industry overall.

Request for Report Sample @ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=9509

Technological Advancements in Welding Consumables and Processes Projected to offer Lucrative Market Opportunities in the U.S.

- Research regarding the usage of biobased raw material sources for the manufacture of welding consumables has started to gain momentum due to the presence of stringent environmental regulations in developed regions. Epoxidized vegetable oils are considered suitable and sustainable ingredients for coated welding electrodes.

- These vegetable oils are used as binders to reduce the diffusible hydrogen content in consumables. Usage of flux-cored wires and SAW flux and wires has increased significantly in the last couple of years; however, coated stick electrodes are still being employed due to their simplicity, low cost, and durability.

- OEM manufacturers in the automobile & transportation industry are currently focusing on new welding methods. The technical team of Honda Motor Co. recently developed a continuous welding process for fabrication of aluminum and steel components through the friction stir welding technique. The technique stabilizes the metallic bond between metal sheets and the welding filler metal by the application of high pressure.

- Usage of stir welding technique has increased the welding strength vis-à-vis the conventional welding processes such as metal inert gas (MIG) welding. Furthermore, it has reduced the body weight of automobile components by nearly 25%, thereby improving the overall fuel economy.

Volatility in Prices of Raw Materials to Hamper Growth of Welding Consumables Market Growth

- The U.S. primarily imports minerals and metal alloys from other countries such as South Africa, the Middle East, and China. Hence, fluctuation in the prices of these materials is estimated to hamper market growth of welding consumables in the U.S. during the forecast period.

- Metals such as iron, copper, and zinc; alloys of steel, nickel, and aluminum; and minerals such as rutile and ilmenite are the key raw material ingredients used in the manufacture of welding consumables. These raw materials are extracted from non-renewable mining sources.

- Broad usage of these raw materials in various end-user industries has affected their overall market price over the past few years. Furthermore, depletion of crude oil sources is another factor leading to volatility in the prices of raw materials in the global market.

- Currently, substitutes for these raw materials are not available. Key end-user markets depend highly upon their availability.

Explore Transparency Market Research’S Award-Winning Coverage of the Global Food and Beverages Industry @ https://www.prnewswire.com/news-releases/despite-political-conflicts-in-middle-east-and-africa-the-global-oil–gas-downhole-cables-market-to-rise-at-7-cagr-and-reach-valuation-of-us-2-1-bn-by-2027-transparency-market-research-301012612.html

Fragmented Nature of U.S. Welding Consumables Market

- The U.S. market for welding consumables is comprised of a number of vendors vying to gain the top market spot. The market features fervent competition among the existing and established players. The vendors in the market are seen focusing on product innovation supported by extensive research and development activities in order to achieve a unique and valued product portfolio.

- Manufacturers are employing the latest technological innovation, and new grades of welding equipment, to differentiate their product from the competition and gain the attention of the users.

- Leading players in the U.S. welding consumable market include llinois Tool Works Inc., Welding Alloys Group, voestalpine Böhler Welding GmbH, The Lincoln Electric Company, Air Liquide S.A., and ESAB.

Request for Covid-19 Impact Analysis @ https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=9509