Filling Machines Market By Study Growth Factors, Types and Applications

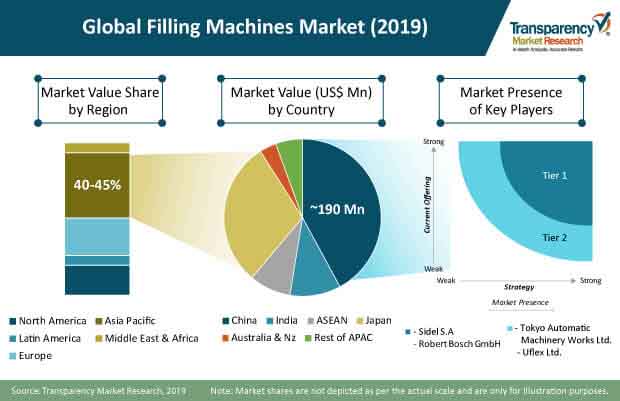

Transparency Market Research delivers key insights on the filling machines market in its published report. In terms of revenue, the global filling machines market is estimated to expand at a CAGR of over 4% during the forecast period of 2019–2027, owing to numerous factors, about which, TMR offers thorough insights and forecasts in the filling machines market report.

Filling machines are packaging machines that measure a product and fill the same in specified packaging products, such as flexible packaging pouches, cans, bottles, etc. The packaging machine industry in the Asia Pacific region is expected to witness enormous growth opportunities in the coming years, due to the substantial increase in packaging consumption in the region. Filling machine manufacturers located in Germany, Italy, and the U.S. could focus on exporting their machinery to developing countries such as China and India. However, it has been observed that, the demand for filling machines in China is largely fulfilled by domestic manufacturers, due to their low-cost offerings and services. Moreover, some filling machine companies believe that, machine manufacturers present in developed countries such as Germany and Italy offer better and advanced technology products with superior quality as compared to Chinese products. Moreover, the sharp growth in organized retail in India and ASEAN countries has led to an increase in processed food consumption, as well as single-use beauty products, which has had a positive impact on the demand for filling machines in developing countries.

Want to know the obstructions to your company’s growth in future? Request a Sample

In the report, TMR proposes that, automatic filling machines are expected to outpace form-fill-seal machines in the market. Key players in the filling machine market are focusing on offering smart maintenance services along with the high optimization of packaging processes in their product lines, as such, escalating the growth of the automatic filling machines market. Considering the filling machine markets in developing countries, small packages such as sachets and pouches are more affordable than large packaging formats. Filling machines are successfully used for packaging in many industries, as they greatly reduce the packaging time as compared to separate machines for each function, such as machines/tools for package forming, filling the finished product, and finally sealing the package. All these factors are contributing to driving the growth of the filling machines market in the near future.

Increasing Adoption of Ultrasonic Sealing Systems in the Filling Machines Market

Ultrasonic sealing provides precise sealing, and thus, results in saving flexible packaging products. Many key manufactures in the filling machines market are using such techniques in order to increase their revenue. For instance,

- In October 2016, Bosch Packaging Technology, Inc., introduced vertical and horizontal flat pouch filling machines with ultrasonic sealing technology options. These machines have the capacity to produce on an average 300 products per minute.

- In 2015, Matix Packaging Machinery LLC launched an upgrade option of ultrasonic sealing for all of its VFFS models.

Looking for exclusive market insights from business experts? Request a Custom Report

Competition Landscape: Filling Machines Market

Some of the key players in the global filling machines market that are included in the report are Tokyo Automatic Machinery, Uflex Ltd., I.M.A. Industria Macchine Automatiche SpA, Hayssen Flexible Systems Srl, Robert Bosch GmbH, Matrix Packaging LLC, Bossar Packaging, Ossid LLC, Nichrome India Ltd., Omori Machinery Co. Ltd., All-Fill Incorporated., GEA Group Aktiengesellschaft, Sacmi Filling S.p.A., Arpac LLC, Fuji Machinery Co. Ltd., Webster Griffin Ltd., Pakona Engineers Pvt Ltd., Mespack SL, and Fres-co System USA, Inc.

Players in the filling machines market are majorly competing in the high speed of packaging, as well as the versatility of filling machines towards easy and quick changeovers. The challenge that arises with the increasing speed of packaging is effective sealing, and as such, companies are introducing new methods for better sealing.

- In February 2017, Nichrome Ltd., India launched Flipack Servo 12k and Maxima 200/400 vertical form-fill-seal machines & filling machines. Flipack Servo 12k is a motorized mechanical filling machine, which ensures consistent fill accuracy and ease in quantity changeover.

You May Also Like PRNewswire on Machine Condition Monitoring Market