Today’s emerging technologies are helping the human being to accomplish a number of assignments and daily works without using their hand, and such a technological breakthrough has represented the world a soft robotic hand which can precisely pack and store fruits and vegetables. Ocado – world’s largest e-commerce supermarket has put a new robotic hand on trial, which is capable of packing and storing fruits and vegetables in the warehouse, without damaging them.

The British online-only supermarket firm has a computerized warehouse in Andover, Hampshire, where robotic hands will be employed for storing and packing fruits and vegetables. The automated storage of Ocado contains specific stuff and goods that used to be manufactured following customer orders. Currently, the items are being selected by a team of the human being. But in the future, the soft robotic hand is expected to replace the human employment.

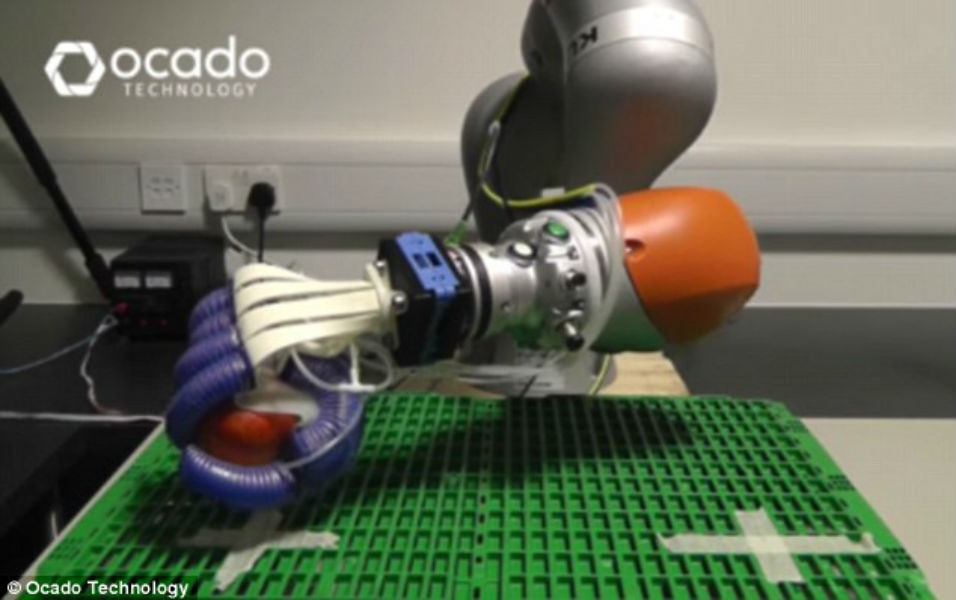

Recently, the grocer Ocado represented the robotic hand which is developed for conducting some human-exclusive tasks like picking fruit and vegetables, without damaging them, and storing them in its warehouses. The robot, dubbed as ‘RBO Hand 2’, has rubber-like chambers which will be used as fingers. The chambers consist of stretchy material and make use of hassled air to clutch objects. The robot is claimed to replace a number of human workers. In simple words, the robotic hand is a perfect technological replacement of human labor.

‘RBO Hand’ is a part of Ocado’s SoMa (Soft Manipulation) assignment – a collaborative project with some leading universities in Italy, Germany, and Austria, as well as Disney research. The development of the robot is intended for offering an automated selection of each and every item, stored in the storehouses of Ocado.

Currently, there are more than 4,000 staffs, employed in Ocado’s storerooms for selecting and packing the stuff of the firm. However, if everything goes accordingly, soon the thousands of employees will be replaced by some such robotic hands. The move of deploying robots in the warehouse will not only trim down the operational expenses of Ocado but also will reduce the human employment almost half.

Earlier to RBO Hand 2, no such machines were there which can grab spongy objects without damaging or hurting them and this was the most challenging factor of robotic hand’s development process. However, currently, the automated machine is on trial period, and if everything goes according to plan, then soon it will be deployed in the firm as a substitute to human employment.